Butterfly-Table for wooden frameworkRandek AB

BS20

Butterfly-Table for wooden framework

Randek AB

BS20

Year of construction

2026

Condition

New

Location

Falkenberg

Show images

Show map

Machine data

- Machine type:

- Butterfly-Table for wooden framework

- Manufacturer:

- Randek AB

- Model:

- BS20

- Year of construction:

- 2026

- Condition:

- new

Price & Location

- Location:

- Falkenberg, Schweden

Call

Details about the offer

- Listing ID:

- A896-820

- Reference number:

- BS20

- Update:

- 22.01.2026

Description

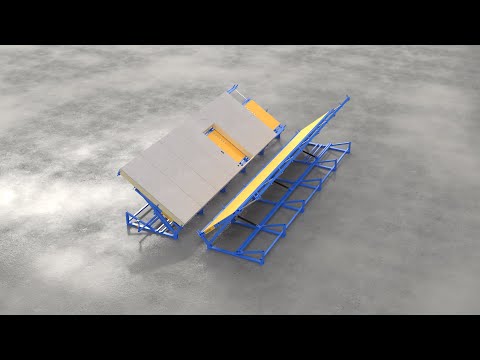

Butterfly Table BS20

Randek butterfly table BS20 is an efficient tool when producing prefabricated walls, roofs, floors, gable ends in timber or steel frame. The tables can be used separate or placed in a line. High quality is achieved due to the clamping function that guarantees the squaring of the building component. The turning of the building element is done with a controlled automatic process. High productivity is achieved; the working table is optimized for prefabricated house production.

Functional description:

The following processes can be done in the working table / butterfly table:

• Automatic turning of building component, the up raiser table raises and flips over the building component during a controlled process to the receiver table, and the building component is turned.

• Squaring of building component, the pneumatically clamping function on the long side of the table presses the building component into a squared high quality building component.

• The table is developed in order to efficiently perform the following processes: building of framework, put on and nail sheets, nailing of plastic of paper foil and insulation of building component.

Technical description:

• Length: Available in lengths of 6000, 7500, 9000 and 12000 mm

• Width adjustment between 2250 – 3100 mm, the adjustment between different widths is easily done with a manual control

• The tables are hydraulically appraisable up to 91 degrees

Gbjdpfj Nn Hyex Advsh

• Pneumatically squaring function on the up raiser table on the long side, stoppers height 160 mm

• The tables are covered with plywood sheets as far as technically possible, the sheets makes it possible to put on sub components and beams easily directly on the table

• The tables are built in strong steel profiles

• The working height of the tables is optimal 620 mm

• Equipped with alongside c-profiles for possible placement of steer stoppers for beam placement

• The tables are completely delivered ready for assembly with very simple installation process. The customer is responsible for supply of motor cover and switcher for hydraulic unit (3kW)

• The tables are designed to make it possible to add a multi function working bridge with nailing or drilling function

• The distance between the tables shall be approximately 1100 mm, depending on the thickness of the building component

Security:

• The machine is equipped with safety stop

CE-marked

Benefits:

• Squared building components due to clamping function

• Controlled and automatic turning of the building component

• Ideal working height

• Flexible adjustment in width

Randek butterfly table BS20 is an efficient tool when producing prefabricated walls, roofs, floors, gable ends in timber or steel frame. The tables can be used separate or placed in a line. High quality is achieved due to the clamping function that guarantees the squaring of the building component. The turning of the building element is done with a controlled automatic process. High productivity is achieved; the working table is optimized for prefabricated house production.

Functional description:

The following processes can be done in the working table / butterfly table:

• Automatic turning of building component, the up raiser table raises and flips over the building component during a controlled process to the receiver table, and the building component is turned.

• Squaring of building component, the pneumatically clamping function on the long side of the table presses the building component into a squared high quality building component.

• The table is developed in order to efficiently perform the following processes: building of framework, put on and nail sheets, nailing of plastic of paper foil and insulation of building component.

Technical description:

• Length: Available in lengths of 6000, 7500, 9000 and 12000 mm

• Width adjustment between 2250 – 3100 mm, the adjustment between different widths is easily done with a manual control

• The tables are hydraulically appraisable up to 91 degrees

Gbjdpfj Nn Hyex Advsh

• Pneumatically squaring function on the up raiser table on the long side, stoppers height 160 mm

• The tables are covered with plywood sheets as far as technically possible, the sheets makes it possible to put on sub components and beams easily directly on the table

• The tables are built in strong steel profiles

• The working height of the tables is optimal 620 mm

• Equipped with alongside c-profiles for possible placement of steer stoppers for beam placement

• The tables are completely delivered ready for assembly with very simple installation process. The customer is responsible for supply of motor cover and switcher for hydraulic unit (3kW)

• The tables are designed to make it possible to add a multi function working bridge with nailing or drilling function

• The distance between the tables shall be approximately 1100 mm, depending on the thickness of the building component

Security:

• The machine is equipped with safety stop

CE-marked

Benefits:

• Squared building components due to clamping function

• Controlled and automatic turning of the building component

• Ideal working height

• Flexible adjustment in width

Documents

Seller

Note: Register for free or log in, to access all information.

Registered since: 2011

Send inquiry

Telephone & Fax

+49 5721 ... show

These listings may also fit your interest.

Listing

Nürnberg

Nürnberg

8,019 km

Sheet metal folder, bending machine

PROD-MASZ Abkantbank24 BiegemaschineProfi Abkantbank RED-2m/1.2 +Ausparrung

PROD-MASZ Abkantbank24 BiegemaschineProfi Abkantbank RED-2m/1.2 +Ausparrung

Listing

Askersund

Askersund

7,593 km

Cutting saw

RandekSP700

RandekSP700

Listing

Gusselby

Gusselby

7,558 km

Handling equipment for finger jointing

Martek

Martek

Listing

Göttingen

Göttingen

7,817 km

Segmented sheet metal folder

PROD-MASZ Abkantbank24 BiegemaschineKlavierbank, Abkantbank mit Segmenten 2m

PROD-MASZ Abkantbank24 BiegemaschineKlavierbank, Abkantbank mit Segmenten 2m

Listing

Bunmahon

Bunmahon

6,749 km

Moulder

SCMTOPSET MASTER 6 HEADS

SCMTOPSET MASTER 6 HEADS

Your listing has been deleted successfully

An error has occurred